The Airtel Green Switch

In the manufacturing world, sustainability was once viewed as a "nice-to-have"—a line item for the CSR report. Today, it is a definitive metric of operational efficiency and market relevance.

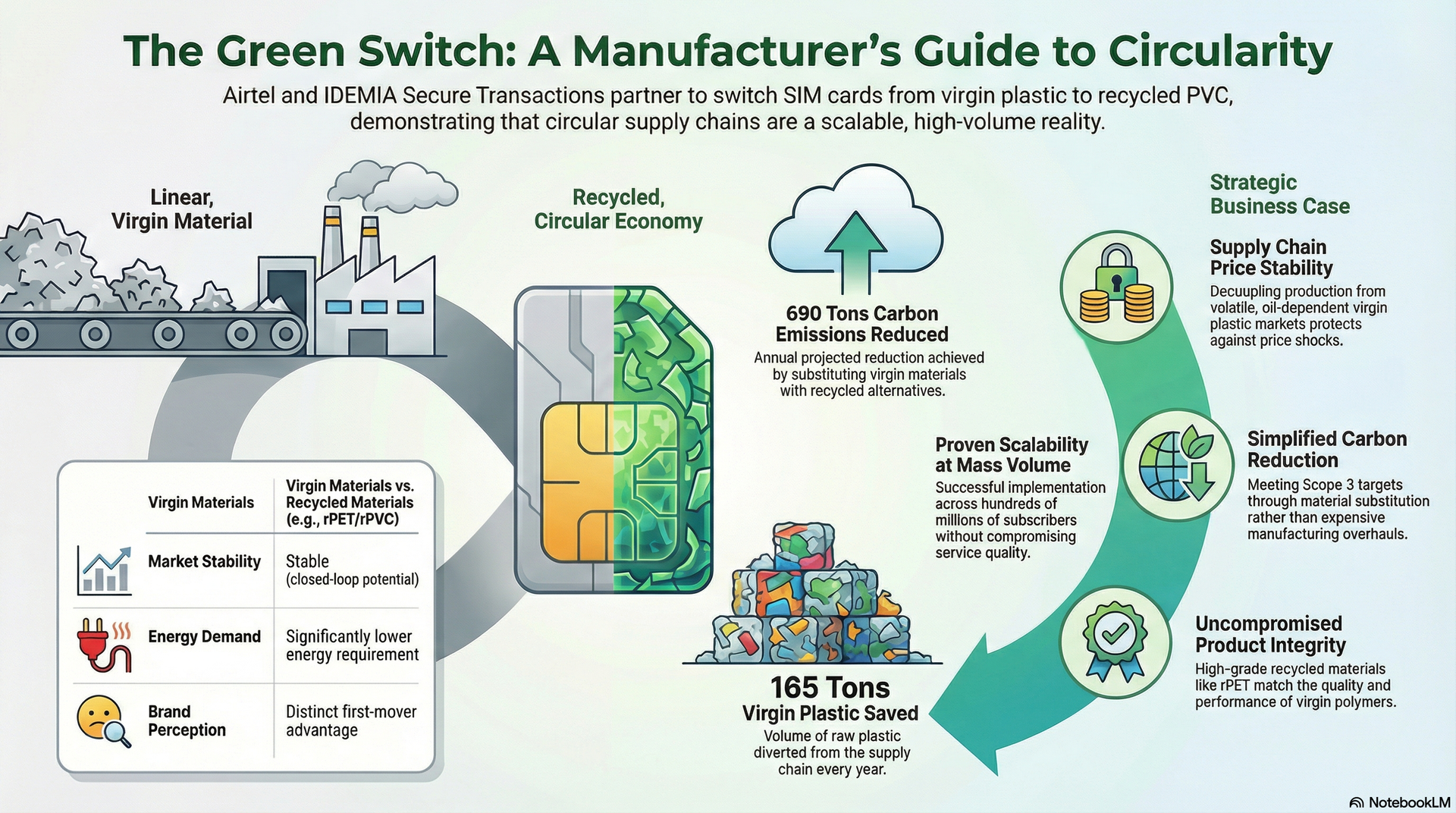

The recent move by telecom giant Airtel to switch to recycled PVC (rPVC) for their SIM cards is not just an environmental win; it is a signal to the market. By partnering with IDEMIA Secure Transactions to replace virgin plastic, Airtel is projected to reduce carbon emissions by 690 tons and save over 165 tons of virgin plastic annually.

For Procurement, Product, and Operations Managers, this is more than a headline. It is a case study in scalability. It proves that transitioning away from virgin materials is no longer a theoretical risk, but a practical, high-volume reality.

Here is the business case for why manufacturers must follow suit—and how recycled materials like rPET are the key to unlocking this value.

1. Decoupling Growth from Virgin Resource Dependency

For years, procurement teams have battled the volatility of virgin plastic markets, often tied closely to fluctuating oil prices. Continuing to rely on virgin polymers exposes supply chains to geopolitical instability and price shocks.

Airtel’s move demonstrates the viability of a closed-loop supply chain. By opting for recycled materials, manufacturers can stabilize their resource input. At Ribotl Solutions, we see this daily: companies that integrate rPET (recycled polyethylene terephthalate) into their product lines are effectively hedging against future raw material scarcity.

2. The Efficiency of Carbon Reduction

Operations Managers are increasingly tasked with lowering Scope 3 emissions. The math behind Airtel’s switch is compelling: a massive drop in carbon footprint simply by changing the material input, without necessarily disrupting the core utility of the product.

Recycled plastics, such as the rPET we process at Ribotl, require significantly less energy to produce than their virgin counterparts. This allows manufacturers to meet aggressive sustainability targets (and regulatory compliance) through material substitution rather than expensive process overhauls.

3. Meeting the "Eco-Conscious" Demand at Scale

Product Managers know that today’s consumer—and B2B client—scrutinizes the supply chain. Airtel is the first Indian telecom operator to make this switch, giving them a distinct first-mover advantage in brand perception.

However, the key takeaway is feasibility. Airtel has hundreds of millions of subscribers. If a supply chain that complex can transition to 100% recycled materials without compromising service quality, the argument that "recycled materials can't handle scale" is officially dead. Whether you are manufacturing consumer goods, packaging, or industrial components, the quality of high-grade rPET matches that of virgin plastic, ensuring your product integrity remains untouched.

The Ribotl Perspective: From Observation to Action

Airtel’s switch to rPVC is a blueprint. For manufacturers using PET, the transition to rPET offers the same strategic advantages.

At Ribotl Solutions, we bridge the gap between waste and resource. We don’t just recycle bottles; we provide a consistent, high-quality stream of rPET that allows Procurement and Operations leaders to build resilient, circular supply chains.

The question for manufacturers is no longer if you should switch to recycled inputs, but how fast you can execute it to remain competitive. Airtel has set the pace. It’s time for the rest of the industry to catch up.